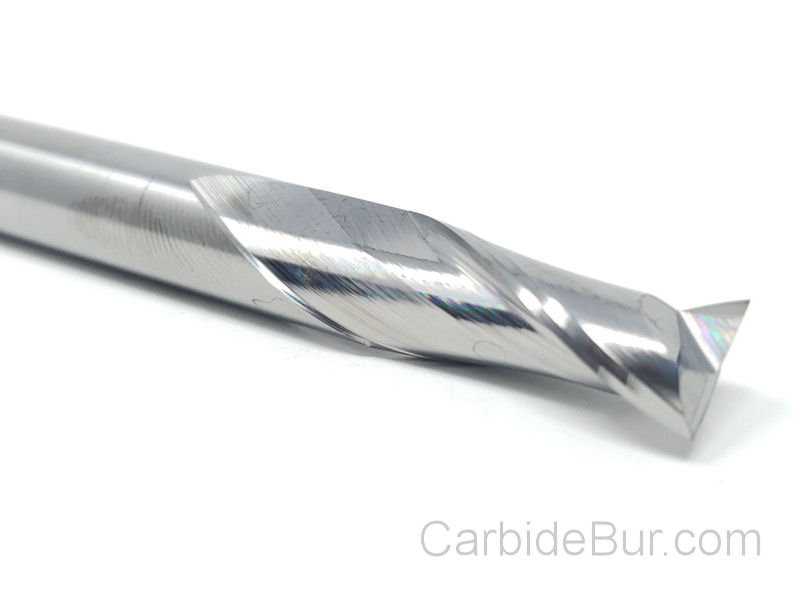

End Mill EM2-0375

Our end mill EM2-0375 is in stock and ships SAME DAY ordered.

Micrograin single end 2 and 4 flute right hand spiral solid carbide end mills

Cutter Diameter: 3/8″

Flute Length: 7/8″

Overall Length: 2 1/2″

Flutes: 2

Click here to order our EM2-0375 End Mill

Solid Carbide End Mill EM2-0375

Exploring the Benefits of the Carbide End Mill EM2-0375

In the world of precision milling, the Carbide End Mill EM2-0375 stands out as a versatile and high-performance cutting tool. Designed with a 1/2 inch diameter, this end mill is engineered to tackle a wide range of machining materials, from hardened steels to aluminum alloys and engineered plastics. Its advanced flute design and sharp carbide edges ensure efficient chip removal and high-speed cutting, making it an invaluable asset for both experienced machinists and creative DIY enthusiasts. The EM2-0375 not only promises outstanding surface finishes but also allows for intricate detailing in every project, transforming your milling endeavors into feats of craftsmanship. Join us as we delve into the remarkable benefits of this cutting-edge tool and explore how it can elevate your milling operations to new heights. Learn more here.

The Power of Precision Milling

Precision milling is an art and science that transforms raw materials into meticulously crafted components. The Carbide End Mill EM2-0375 plays a crucial role in this process, offering users a precise, efficient, and versatile tool. With its innovative design, it enhances the capabilities of both professionals and hobbyists, making complex milling tasks more achievable.

Unveiling the End Mill EM2-0375

The End Mill EM2-0375 is engineered for excellence in precision milling. With its 1/2 inch diameter and carbide composition, it excels in delivering exceptional performance across various machining tasks. Its sharp carbide edges and advanced flute design ensure efficient chip removal, enabling high-speed and precise cutting.

Designed to work seamlessly with a wide range of materials, this end mill is a testament to cutting-edge engineering. Whether you’re machining hardened steels or aluminum alloys, the EM2-0375 stands as a reliable partner.

The tool’s versatility offers unmatched surface finishes and intricate detailing, making it a favorite among machinists and DIY enthusiasts alike. For more details on the EM2-0375, visit Carbide Burr and explore its full potential.

Key Features and Advantages

The EM2-0375 boasts several key features that set it apart in the realm of cutting tools. Firstly, its carbide construction ensures longevity and durability, even under demanding machining conditions. This makes it a cost-effective choice for professionals.

Another highlight is its flute design, which promotes efficient chip evacuation. This prevents clogging and ensures smoother operations. The result is a tool that maintains its sharpness and precision, reducing the need for frequent replacements.

Moreover, the end mill is designed for high-speed cutting, which significantly enhances productivity. The combination of these features makes the EM2-0375 a preferred choice for achieving superior milling results. Discover more at Carbide Bur.

Materials and Applications

The versatility of the Carbide End Mill EM2-0375 extends across several materials, making it an invaluable tool for various applications. Its adaptability ensures that it meets the specific needs of each material, enhancing both efficiency and quality.

Mastering Hardened Steels

When it comes to hardened steels, the EM2-0375 excels by offering unparalleled cutting precision. Hardened steels often present challenges due to their toughness, but this end mill’s carbide composition provides the necessary strength to tackle these materials.

Benefits include:

-

Enhanced durability: The carbide end mill can withstand the high pressure and heat generated during machining.

-

Superior finish: Ensures smooth surfaces on hardened steels.

-

Precision detailing: Allows for intricate designs and patterns.

By mastering hardened steels, the EM2-0375 expands its utility in industries requiring durable and precise components. Learn more about its capabilities with hardened steels at More Cutting Tools.

Versatility with Aluminum Alloys

Aluminum alloys are widely used due to their lightweight and corrosion-resistant properties. The EM2-0375 performs exceptionally well with aluminum, providing clean cuts and minimal tool wear. Its flute design aids in rapid chip removal, reducing downtime and improving efficiency.

Key features of milling aluminum:

-

High-speed capability: Allows faster operations without compromising quality.

-

Smooth finishes: Reduces the need for additional polishing.

-

Versatility: Suitable for a range of aluminum grades.

The end mill’s ability to handle aluminum alloys makes it a versatile tool for various industries, from automotive to aerospace.

Benefits for Engineered Plastics

Engineered plastics require careful handling to avoid material distortion or damage. The EM2-0375 is adept at machining these materials, offering precision without sacrificing material integrity. Its sharp edges and efficient chip evacuation make it an ideal choice for these applications.

Advantages include:

-

Reduced material distortion: Maintains the structural integrity of plastics.

-

Precision cuts: Ensures accurate and clean edges.

-

Versatility: Capable of handling a variety of engineered plastics.

The EM2-0375’s proficiency in working with engineered plastics opens up opportunities for innovation in product design and manufacturing. For further insights, visit Carbide Burr.

Carbide burs (burrs) are tools that are used for precision in cutting, grinding, and shaping the material

with which they are being worked. Additionally, they are used for deburring, where burrs, excess

materials, sharp edges, and weld beads are removed. Use carbide burs in industrial tools, such as air

tools (e.g., die grinders), engravers, flexible shafts, and pendant drills, as well as for hobbies (e.g.,

Dremel tools). Their uses are varied and diverse, such as jewelry work, metalworking, welding,

woodworking, and cover a range of industries, including aeronautics, aviation, automotive, dentistry,

and metal and stone working.

Carbide burs (burrs) are generally composed of titanium or tungsten; diamond is the only material on

the Mohs scale that is harder and also used for drill tips. This means they are ideal for multiple purposes

due to the fact that they maintain sharper cutting edges for longer periods of time due, and tolerate

higher temperatures without warping when you apply friction. Carbide burs (burrs) maintain their sharp edges 10-20 times longer than a stainless-steel bur (burr), depending on the

frequency of use and the materials used with.

Carbide Bur Cutting Tools can be used on:

Aluminum

Brass

Bronze

Carbon fiber

Cast iron

Ceramics

Copper

Fiberglass

Gold

Hard rubber

Plastic

Platinum

Silver

Steel

Stone

Titanium

Wood

Zinc

Burs (burrs) come in a variety of shapes and sizes, each of which can be used for different purposes:

Arch ball/pointed nose – engraving, texturing, increasing hole size

Ball – concave cuts, hollowing, shaping, carving. Useful for wood, stone, metal engraving.

Ball nose cone – rounding edges, surface finishing, tight spaces, and angles.

Carbide Ball nose cylinder – contour finishing

Ball nose tree (also known as tapered) – concave cuts and rounding edges

Cone – rounding edges, surface finishing, tight spaces, hard to reach areas.

Cylindrical – contour finishing and right-angled corners

Cylindrical end cut – contour finishing

Carbide Cylindrical no end cut – contour finishing

Flame – channel work and shaping

Inverted cone – v-cuts and rear-side chamfering

Oval – die grinding and engraving

Pointed tree – concave cuts, rounding edges, access to hard-to-reach areas, and acute angles.

Rounded tree – concave cuts and rounding edges

Burs (burrs) also come in a variety of ranges, each of which has a specific benefit in their use:

Alloy-specific – heads have varying shapes used with certain metal alloys – used in the

aerospace/aviation industry

Base metal range – used for deburring on softer metals

Bolt remover range – used for the removal of broken studs

Foundry metal range – used for deburring on harder metals, stone, etc.

Inox range – specifically used with stainless steel

Locksmith range – used by locksmiths

Long shank range – general-purpose; long shafts useful for deeper, hard-to-reach areas

Miniature range – miniature heads useful for engraving and fine detail work

New geometry range – used for all general metal removal

Steel range – heads have specialized fluting to cut stainless steel

Universal range – general-purpose, best on metals such as copper, iron, nickel, and steel

Carbide burs (burrs) require a bit of special care to keep them performing optimally. To preserve the life

of your carbide burs, ensure your handpiece does not wobble. The speed of your rotary tool

should not exceed 35,000 RPMs, and speed should be gradually increased. Please note, however,

that higher speeds will prevent flute clogging inside the bur. If you apply too much pressure to the

bur (burr), the edges may chip, resulting in premature dulling.

Choose Double Cut or Single Cut Carbide Bur?

![]()

Double Cut

Our double cut carbide burs allow for rapid stock removal in harder materials. The addition of the left hand flutes reduces the pulling action, allowing better operator control. Double cut reduces the size of the chips and can be used at slower than normal speeds.

Single Cut

Our single cut carbide burs are for general purpose and designed for cast iron, steel, some copper and brass, and other ferrous materials. Single cut will give good material removal and good workpiece finishes.

Non-Ferrous Aluminum Cut Carbide Burs

Use our aluminum cut carbide burs on non-ferrous materials such as aluminum, copper and magnesium.

Our USA made carbide burs are used on hard materials including steel, aluminum and cast iron, all types of stone, ceramic, porcelain, hard wood, acrylics, fibreglass and reinforced plastics. When using aluminum cut burs on soft metals such as gold, platinum and silver, our burs are perfect because they will last a long time with no breaking or chipping.

Try our 1/4” to 1/8” Collet Reducer

Allows you to use 1/8” shank carbide bits in your 1/4” die grinder

Uses for Carbide Bur Die Grinder Bits

Carbide burs are widely used in metalworking, tool and die making, engineering, model engineering, wood carving, jewelry making, welding, chamferring, casting, deburring, grinding, cylinder head porting and sculpting. Carbide burs can be used in the aerospace, automotive, dentistry, stone and metalsmith industries.

All our USA made carbide bur cutting tools ship SAME DAY ordered by USPS Mail with online tracking.

We can also dropship the solid carbide end mill for you, if interested in joining our FREE dropship program.

We accept debit and all major credit card payments including Visa, MasterCard, Discover, American Express and PayPal. Fast and easy secure checkout with no account or login required. If you have any questions, visit our FAQ page or contact us here.

Follow us on Facebook, Twitter and Instagram

Return to CarbideBur.com

Carbide Burs – 1/4″ on 1/8″ Shanks – Accessories – Aluminum Cut – Bur Sets – End Mills – Long Shank – Solid Burs